Boron nitride is a crystal composed of nitrogen and boron atoms, with a chemical composition of 43.6% boron and 56.4% nitrogen. It has four different variants: hexagonal boron nitride (hBN), cubic boron nitride (cBN), rhombic boron nitride (rBN), and wurtzite boron nitride (wBN). At present, the application of boron nitride in the market is mainly focused on hexagonal boron nitride and cubic boron nitride.

Hexagonal boron nitride powder

Given the excellent high-temperature resistance, thermal shock resistance, high-temperature stability, lubrication, electrical insulation, corrosion resistance, and easy machinability of hexagonal boron nitride, it has a wide range of applications in electronic device insulation, thermal management, antioxidant additives for refractory materials, corrosion-resistant and high-temperature resistant boron nitride ceramic materials, atomic structure reactor structural materials, and nozzle materials for aircraft/rocket engines.

In the paint industry, the use of hexagonal boron nitride is mainly due to its excellent properties such as high temperature resistance, lubrication, and corrosion resistance. Especially at high temperatures, hexagonal boron nitride still has good lubrication and oxidation resistance.

Boron nitride coating

Hexagonal boron nitride has a very low friction coefficient and excellent self-lubricating performance, making it a very important anti friction and self-lubricating coating material. It is suitable for soft lubrication parts of high-temperature wear-resistant coatings above 1000 ℃, such as high-frequency plasma arc insulators, anti neutron radiation coatings, high-temperature wear-resistant coatings, etc.

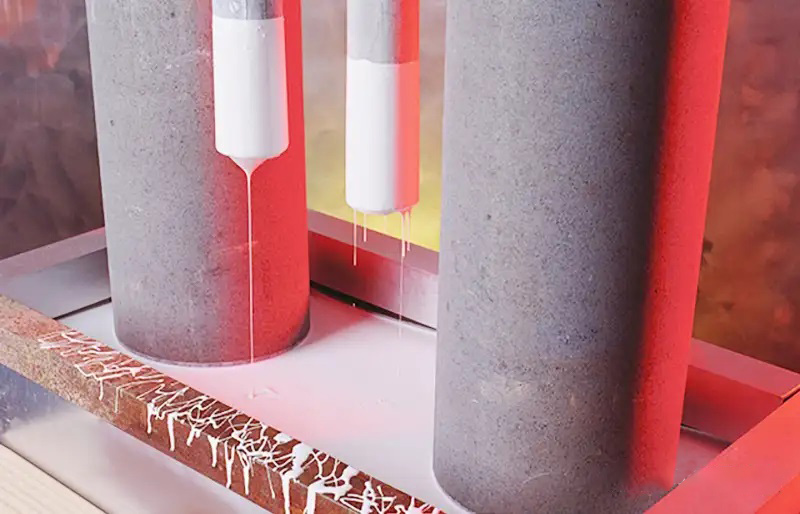

Boron nitride based coatings have good lubrication performance at high temperatures and are an ideal release agent. Therefore, they can be used as a release (anti sticking) agent for hot pressing of ceramics, glass forming, and coating of metal casting. Moreover, coating can reduce or prevent chemical reactions between the substrate and the melt, thereby extending its service life.

Hexagonal boron nitride

The main applications of boron nitride coatings are:

Release agents, lubricants, and protective coatings: At extremely high temperatures, hexagonal boron nitride can still maintain its lubricity and inertness, thus preventing adhesion, extending the life of the die/mold, improving the surface smoothness of the product, and shortening production time.

Metal forming field: Applying boron nitride coating to the surface of molds in contact with hot or molten metal can prevent corrosion, avoid chemical erosion, and make demolding easier. It can be applied in fields such as casting, stamping, forging, and powder metallurgy.

Boron nitride coating

In the field of glass manufacturing: Boron nitride has high-temperature lubrication performance, and most glass does not bond with boron nitride. Therefore, using boron nitride coating in the glass processing process can minimize surface defects of glass products and make it easier to demold.

In the field of sintering and molding, the sintering of metal and ceramic powders is usually carried out on graphite plates. Applying boron nitride coating on the graphite plates can significantly eliminate the pollution, reaction, and bonding phenomenon of carbon on the sintered parts that may occur at the sintering temperature.

Previous:Modification of xylene resin with p-tert butylphenol

Next :Last

Using p-tert butylphenol as an inhibitor in the pr...

Boron nitride release agent used for aluminum melt...

Application of p-tert-octylphenol in offset printi...

P-tert butylphenol as a reaction termination agent...

Application of p-tert-octylphenol in the tire indu...

Using p-tert butylphenol as a UV absorber

Follow Us

+86 13953370669

+86 13953370669

+86 13953370669

157012497@qq.com

185 Xincun West Road, Mashang Street Office, Zhangdian District, Zibo City, Shandong Province, China

Copyright © 2024 chuanhexicai.cn Shandong Chuanhe New Materials Co., Ltd All Rights Reserved